Contents

- 1 Refrigeration Cycle Diagram: How It Works and What You Need to Know:

- 2 What is the purpose of Compressor in refrigeration cycle?

- 3 How does a refrigeration Condenser work?:

- 4 What is a thermostatic expansion valve (TXV or TEV) or Metering valve: Throttling device?

- 5 Evaporator: Absorbing Heat

- 6 Why must the critical temperature of a refrigerant be high?

- 7 What is Heat?

- 8 What is a ton of refrigeration?

- 9 What is subcooling?

- 10 What is superheating?

- 11 Refrigeration cycle PH diagram

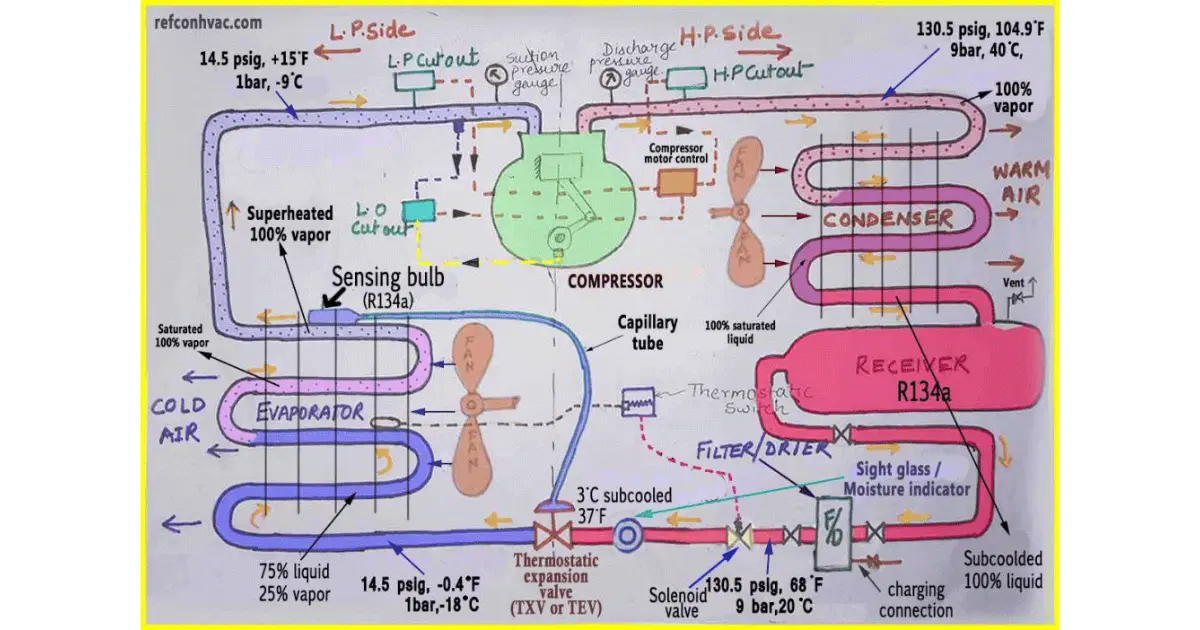

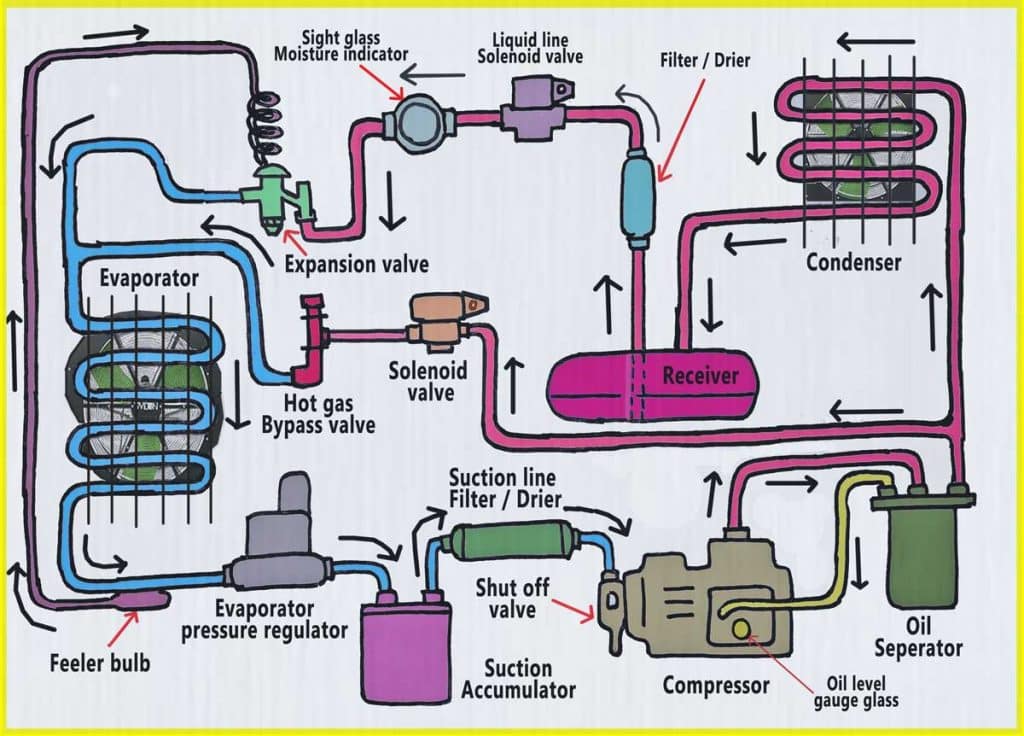

Refrigeration Cycle Diagram: How It Works and What You Need to Know:

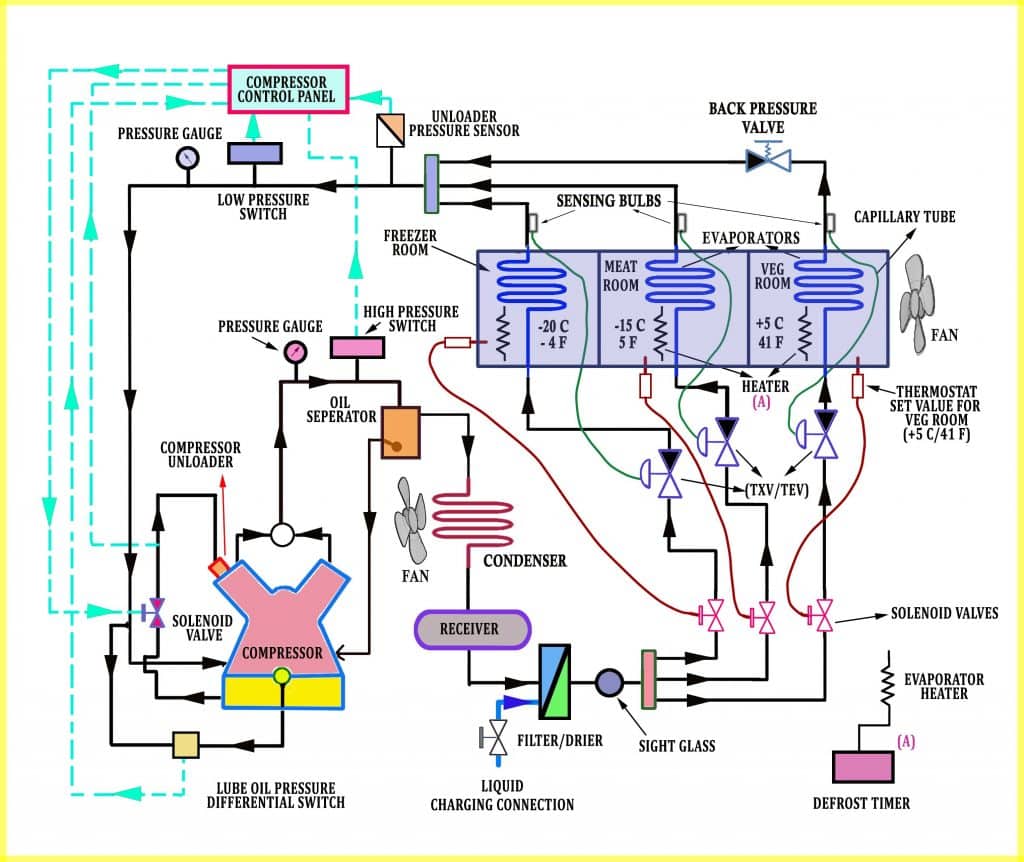

A basic refrigeration cycle consists of 4 major components: Compressor, Condenser, Thermostatic Expansion Valve (TEV), and Evaporator. These components allow the heat to transfer from one location to another, creating a cooling effect in the desired area.

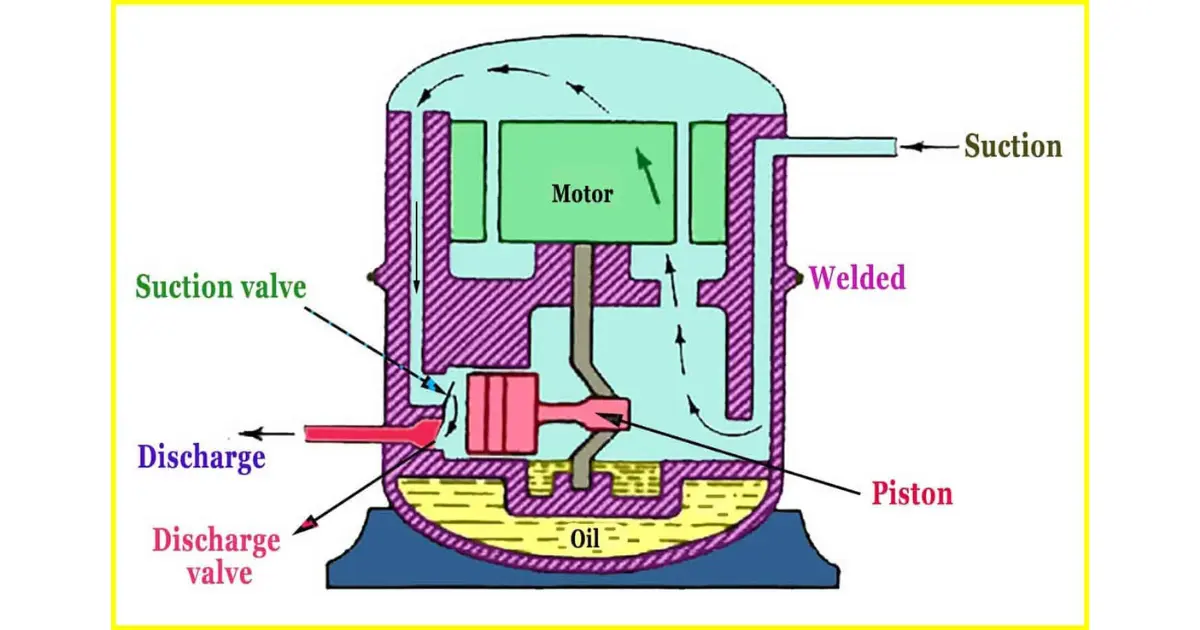

What is the purpose of Compressor in refrigeration cycle?

The compressor in a refrigeration system is responsible for compressing the low-pressure, dry gas refrigerant from the evaporator, thereby increasing its pressure and temperature to match that of the condenser. This process facilitates the flow of refrigerant throughout the system.

The most easily recognizable compressor is a positive displacement type, which is the reciprocating or screw compressor or scroll compressor.

Let’s consider the example of a refrigerator: when the refrigerant passes through the evaporator, it undergoes a phase change from a liquid to a vapor as it absorbs heat from the refrigerated space.

To convert the refrigerant back from vapor to a liquid state, the compressor comes into action. The compressor increases the temperature and pressure of the refrigerant, causing it to transition from a low-pressure, low-temperature vapor to a high-pressure, high-temperature vapor.

This high-pressure, high-temperature vapor refrigerant is then transformed into a high-pressure, low-temperature liquid refrigerant by circulating the outside surrounding air over the condenser coils using a fan. It’s important to note that the temperature of the refrigerant at this stage is nearly the same as the outside ambient temperature.

In the absence of a compressor, the heat may start to flow from the condenser to the outside air.

Like in hotter regions the outside air temperatures can go up to 42°C – 48 °C with this hot outside air, the refrigerant gets cooled back from vapor to the liquid state.

Like in hotter regions the outside air temperatures can go up to 42°C – 48 °C with this hot outside air, the refrigerant gets cooled back from vapor to the liquid state.

This is possible due to the refrigerant property which is the “critical temperature of a refrigerant”.

What is critical temperature?

The critical temperature of a refrigerant is the highest temperature at which it can exist as a liquid, regardless of the pressure applied. Above this temperature, the refrigerant cannot be liquefied by pressure alone and exists only as a gas. This property is crucial in designing and operating refrigeration and air conditioning systems for several reasons.

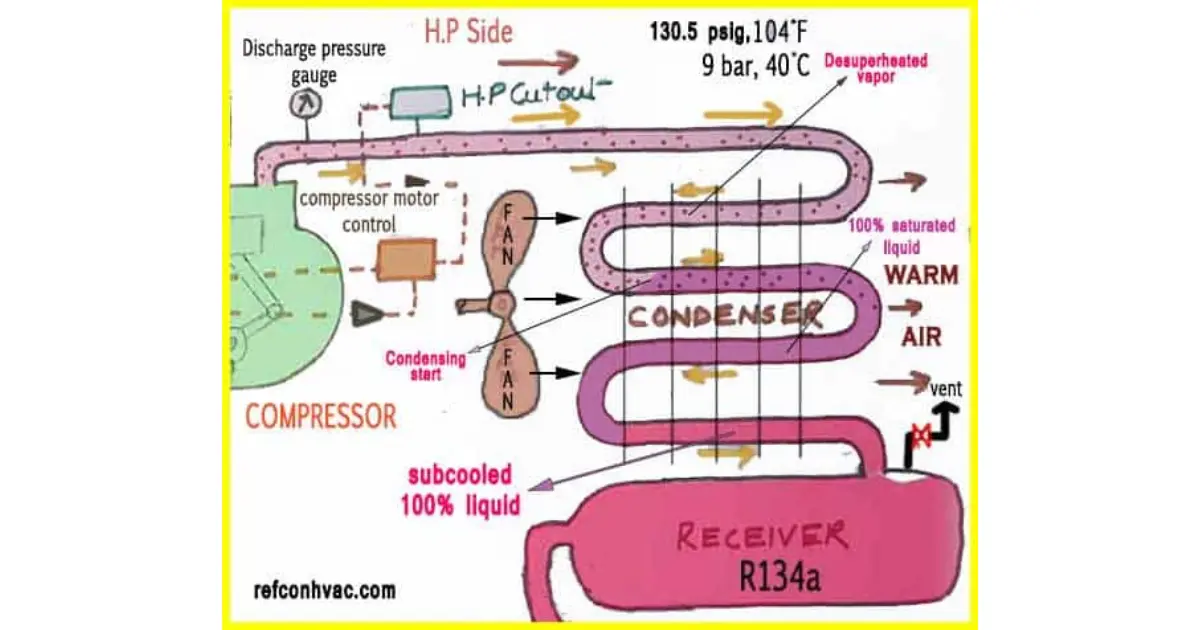

How does a refrigeration Condenser work?:

The refrigeration condenser coil takes in hot, high-pressure gas from the compressor and cools it to remove first the superheat and then the latent heat so that refrigerant condenses back to a liquid state.

What is latent heat?

Latent heat is the heat required to change a substance’s state (solid to liquid or gas) without changing its temperature. For example, when ice melts to water or boils to steam, latent heat is absorbed or released, but the substance’s temperature does not change during this process. This concept is essential in understanding how substances absorb or release energy during state changes.

Condenser cooling mediums are usually fan or water

The small condensing surface required by a domestic appliance such as a fridge/freezer uses the outside metal skin of the body itself as a surface heat exchanger.

The small condensing surface required by a domestic appliance such as a fridge/freezer uses the outside metal skin of the body itself as a surface heat exchanger.

In such a construction, the condenser tubes are mechanically fixed in close contact with the skin, so that heat gets conducted through to the outside air by natural convection.

Types of condenser:

- AIR-COOLED CONDENSERS

- WATER-COOLED CONDENSERS

- EVAPORATIVE CONDENSERS

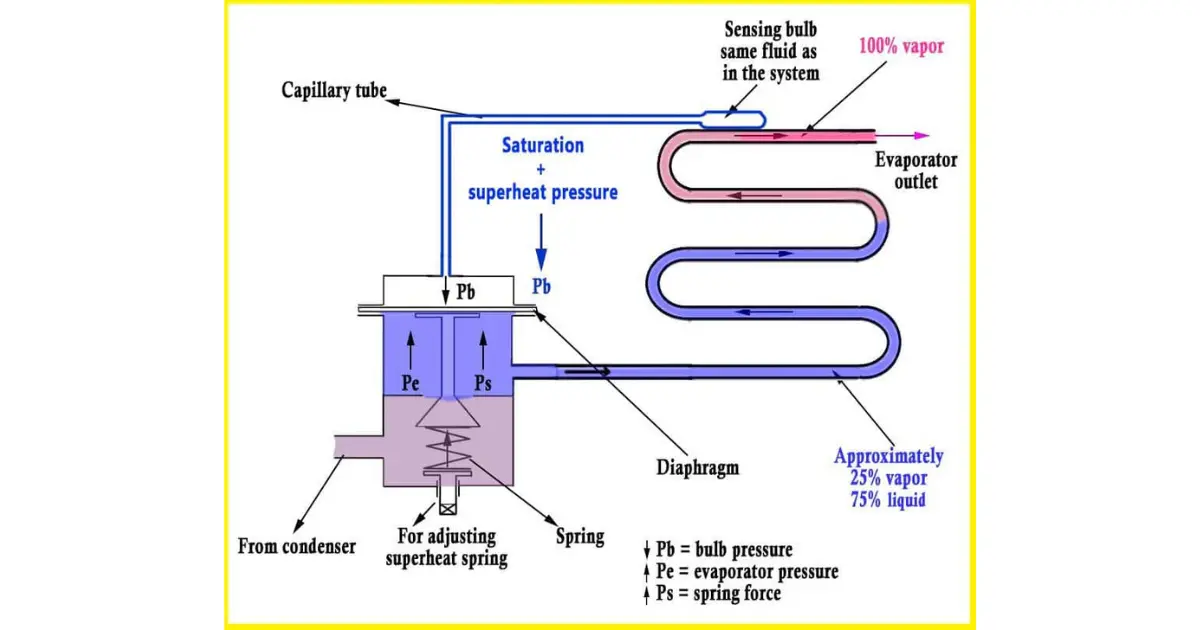

What is a thermostatic expansion valve (TXV or TEV) or Metering valve: Throttling device?

A thermostatic expansion valve (TEV), also known as a metering device, is an essential component in a refrigeration or air conditioning system. It basically regulates the flow of refrigerant inside the evaporator coil. TEV maintains a certain degree of superheat so that liquid refrigerant does not enter into the suction side of the running compressor. Also, TEV maximizes the heat exchange between the Evaporator coil and the refrigerated space.

The unit controls the flow through the evaporator so that the condition of the refrigerant leaving the evaporator is a slightly superheated gas.

The metering valve or expansion valve in HVAC system ensures that the full latent heat has been absorbed by the refrigerant which in turn reduces the mass flow rate required by the system.

A sensing bulb with a good thermal contact is fastened at the evaporator outlet to make sure the refrigerant gas leaving the evaporator outlet is superheated.As the bulb temperature increases, the refrigerant within the bulb expands thereby opening the expansion valve allowing more gas to flow through the evaporator.

When the refrigerant flow becomes excessive, then the temperature will fall, reducing the pressure within the bulb, hence closing the expansion valve.

When the refrigerant flow becomes excessive, then the temperature will fall, reducing the pressure within the bulb, hence closing the expansion valve.

The capillary tube is used almost exclusively in small refrigeration and air conditioning systems.

Another factor takes place across the Thermostatic expansion valve(TEV), ie. the flashing effect. We know (Gay-Lussac’s Law) Pressure Temperature Law that pressure is directly proportional to temperature for a given amount of gas at constant volume.

Therefore as the pressure drops due to the throttling effect of the expansion valve, the liquid refrigerant temperature goes down by extracting heat from the remaining refrigerant at the condenser side. Due to the loss of heat in the remaining refrigerant, it starts to evaporate or flash to the vapor state. This process is called “flashing”.

As per the above thermostatic expansion valve diagram, when the evaporator and TEV valve is located vertically above the receiver, vapor or flash gas forms in the liquid line as the liquid refrigerant has to overcome the vertical head.

The expansion valve is designed to handle liquid and not a

“mixture of vapor and liquid” to avoid TEV malfunction.

The thermostatic expansion valve (TEV) plays a vital role in controlling and metering the flow of liquid in the system.

By connecting a sensing bulb via a capillary tube to the evaporator outlet filled with the same system refrigerant.

Avoid a flash gas problem by providing enough subcooling to the liquid refrigerant in the condenser. Liquid filled inside the sensing bulb is the same as that of the system (R134a), and the reason is:

- To get the same expansion as that of the system refrigerant, ie. R134a.

- To avoid contamination if the diaphragm ruptures or leaks.

TEV operation and it’s working:

- Bulb pressure on one side of the diaphragm tends to open the valve.

- Evaporator pressure on the opposite side of the diaphragm tends to close the valve.

- Spring pressure applied to the pin carrier gets transmitted through the pushrods to the evaporator side of the diaphragm. This assists in closing the valve.

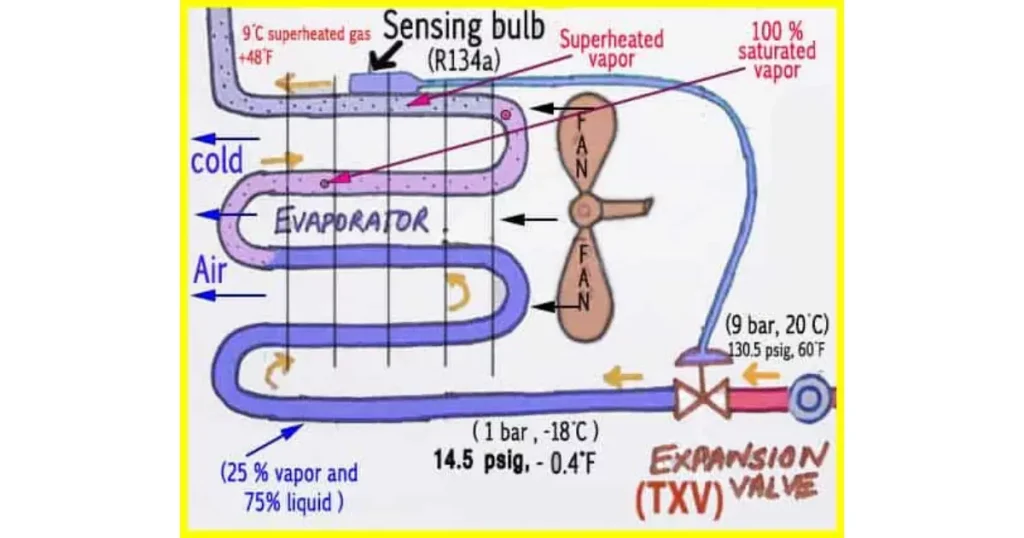

Evaporator: Absorbing Heat

The evaporator plays a critical role in refrigeration systems by transforming low-pressure, low-temperature liquid refrigerant into a vapour at low pressure but higher temperature. This transformation occurs as the evaporator absorbs heat from the environment within the refrigerated space.

As the refrigerant circulates through the evaporator, it captures heat from the space that requires cooling, effectively reducing the temperature of that area. The refrigerant then exits the evaporator as a vapour.

Strategically located within the space that needs cooling, the evaporator operates at a temperature lower than its surroundings, maximizing its heat absorption efficiency. To optimize this heat transfer, the design of the evaporator coil is crucial.

By incorporating fins and fans, the surface area of the coils is increased, thus accelerating the airflow over the evaporator, which enhances the heat absorption capacity.

However, in environments with high humidity, there’s a tendency for ice to form on the evaporator coils. This ice layer can impede the heat transfer process. To counteract this, defrosting mechanisms, such as electric heating coils, are installed adjacent to the evaporator coils. These elements gently warm the coils, causing any accumulated ice to melt and subsequently drain away, thereby maintaining the efficiency of the evaporator in heat absorption.

Types of evaporators:

- AIR COOLING EVAPORATORS

- LIQUID COOLING EVAPORATORS

Why must the critical temperature of a refrigerant be high?

The critical temperature of a refrigerant is the temperature above which vapor refrigerant remains in the vapor state and cannot be liquefied even after passing through the condenser or any cooling medium at any given pressure.

This happens only when the refrigerant temperature reaches beyond its critical temperature, i.e. when a refrigerant has a low critical temperature.

So, it’s better to select a refrigerant having a high critical temperature to be able to condense these gases into liquid form at higher ambient temperatures.

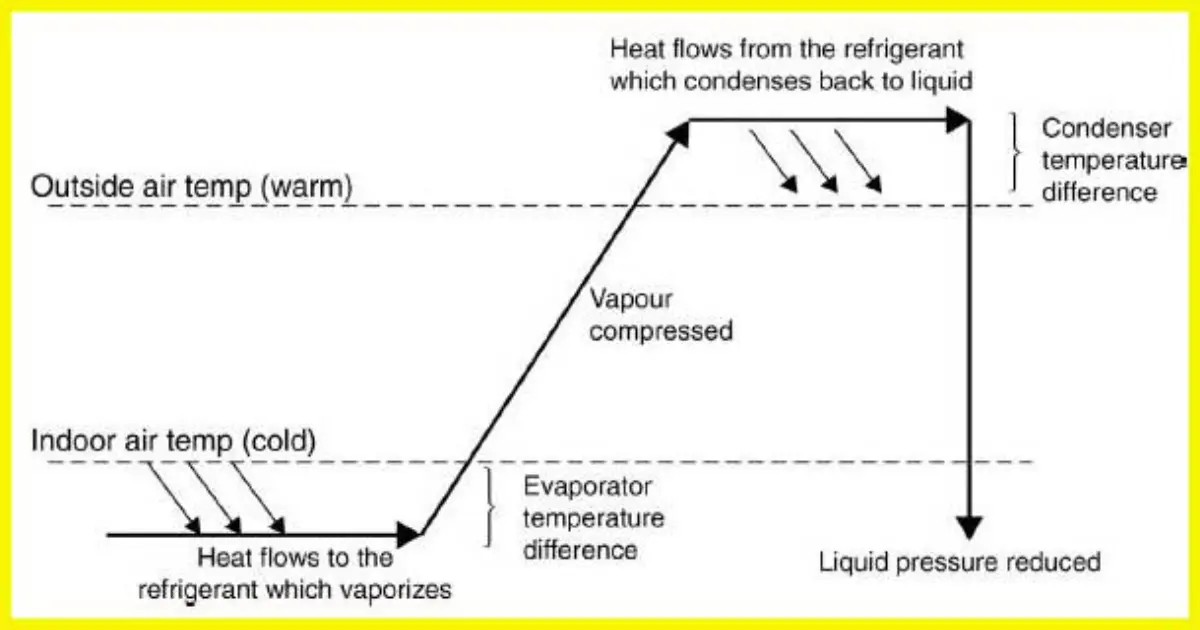

What is Heat?

Heat is a form of energy where every object on earth contains heat energy in both quantity and intensity. Heat intensity is measured by its temperature, commonly in either degrees Fahrenheit (°F) or degrees Celsius (°C).

Removing all the heat from an object decreases its temperature to -459.6°F [-273.2°C].

This temperature is referred to as “absolute zero” and is the temperature at which all molecular activity stops. The quantity of heat contained in an object or substance is not the same as its intensity of heat.

For example, the hot sands of the desert contain a large quantity of heat, but a single burning candle has a higher intensity of heat.

Air-conditioning and refrigeration systems use the principles of heat transfer to produce cooling and heating. The three principles discussed in this topic are:

- Heat energy cannot be destroyed; it can only be transferred to another substance

- Heat energy flows from a higher-temperature substance to a lower-temperature substance

- Heat energy is transferred from one substance to another by one of three basic processes

To produce a cooling effect, remove heat from the substance by transferring it to another substance.

What is a ton of refrigeration?

A ton of refrigeration is the amount of heat in BTU (British thermal unit) required to melt one ton, i.e. 2000 lb (907.18 kg) of ice over a period of 24 hours. Therefore, one ton (2000lb) of ice melts to absorb 288,000 Btu of heat. Similarly, a one-ton air conditioner absorbs 288,000 Btu of heat in 24 hours.

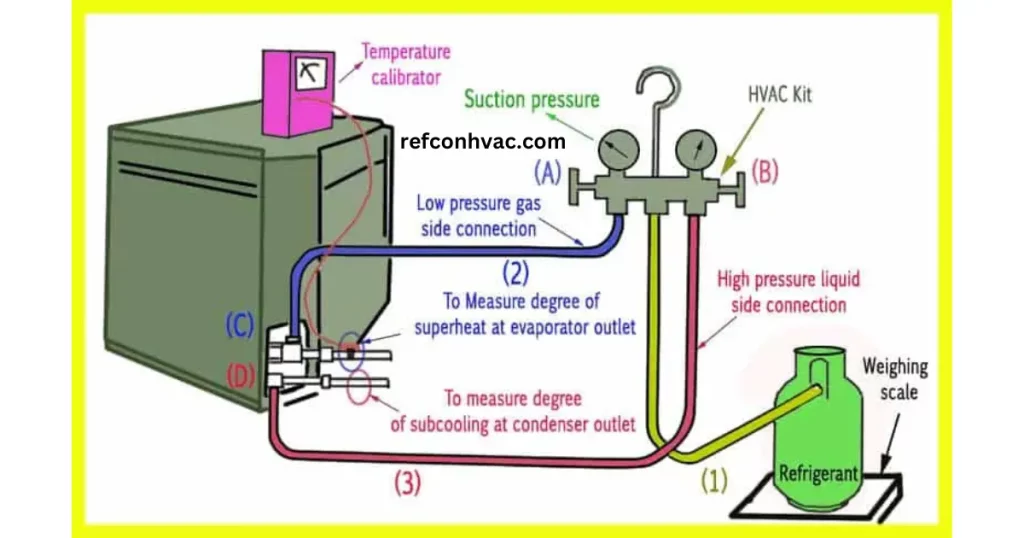

What is subcooling?

Subcooling means cooling the refrigerant below its condensing temperature, were all vapors are turned into 100% liquid. Cooling further below this temperature is called “Subcooling”.

The advantage of subcooling:

- To reduce flash gas formation or vapor formation during the process of expansion in the thermostatic expansion valve (TEV).

- To reduce the specific volume occupied by the refrigerant and, thereby, increase the evaporator cooling capacity.

- Additionally, increased evaporator efficiency extracts more heat from the room to be cooled.

What is superheating?

Superheating means adding more heat to vapor refrigerant after it has been converted from its liquid state to a vapor state inside the evaporator coil, as the refrigerant absorbs heat from the surrounding area.

Cooling is achieved by recirculating the room air over the evaporator coils.

The compressors used in many refrigeration system designs are of the positive displacement type. If, by any chance, refrigerant enters in liquid form in large quantities, it can cause severe damage to the compressor’s components.

As the liquid is incompressible, the refrigerant needs to enter in a gaseous form. This is why refrigerants must be superheated before entering the compressor’s suction

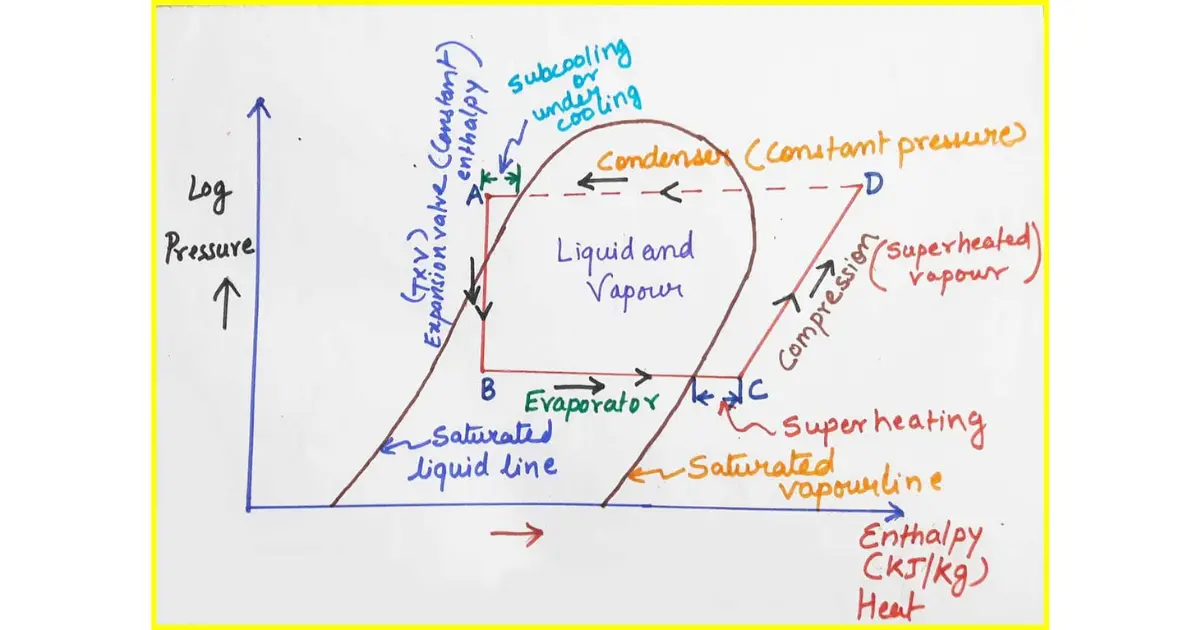

Refrigeration cycle PH diagram

A Pressure-Enthalpy (P-H) diagram is a graphical representation of the thermodynamic properties of a refrigerant, typically used in the analysis and design of refrigeration cycles.It is also known as Mollier diagram.

- C → D: low-pressure vapor refrigerant flows into the compressor suction and discharges into compressed high-pressure vapor.

- D → A: pressurized refrigerant vapor condenses in the liquid state at constant pressure, rejection of heat to the environment.

- A → B: liquid refrigerant flows through the throttling expansion device at constant enthalpy, to a two-phase state flashing as the pressure drops into 25% vapor and 75% liquid. Flashing lowers the coolant temperature to a saturation temperature at the low-side pressure.

- B→ C: Low-temperature refrigerant receives heat from the environment and continues to evaporate as it flows at constant pressure through the evaporator.

Refrigeration cycle: HVAC system basics and refrigerant charging from r/HVAC

well done explanation for basic refrigeration system

Pretty portion of content. I just stumbled upon your blog and in accession capital to say that I acquire actually enjoyed account your weblog posts. Anyway I will be subscribing on your augment or even I success you access persistently quickly.| а

This site has helped me with all that I have been looking for